FURKA AG

First-Class Service

First-Class Service

- Customer service, also on site

- Planning and designing, CAD 2D and 3D

- Execution of CNC customer orders

- Prototype production

- Optimization and revision according to Material

and functional testing - Assembly and Fullfillment Services

- Retrofit Services

Product range

- Disc brake pads

- Drum brake linings

- Band brake pads

- Damping components

- Brake system components

Comprehensive

services

Holistic consultancy

Whether it is noise generation, lack of brake performance or wear, we are happy to advise you in finding a solution for a more powerful system. The effectiveness and reliability of a braking system depends on various boundary conditions and environmental influences – please contact us.

Friction material development as per customer specification

If the appropriate friction lining is not available in our current product portfolio, we will develop it according to customer specification and check the required characteristics on our test facilities.

Retrofit of friction pad carrier and -band

We are happy to take care of the repair of friction pad pad carriers and friction liner bands for continued trouble-free and safe operation. Of course, we also take care of applying the pads and liners by means of an adhesive or rivet connection, according to your specifications.

Production, machining and assembly

Friction material qualities developed and manufactured by us are processed into the pad geometries as specified by the customer thanks to a variety of press molds and a flexible and agile production of individual parts to batch sizes of several thousand pieces. The experienced team and our machine park with special and CNC processing machines as well as a water jet cutting system allow us to confidently handle even non-everyday requirements. The production of sophisticated flooring pad geometries and dimensions is the order of the day for us.

F E E L

Furka Extended Engineering Link

Our Engineering & Management Team is linked to strong network of Business Partners in the Railway Industry, well consolidated and established over time and through significant activities in International Projects.

This key background fact fuels our capability to offer a really effective support in the Project Management area too, extending much beyond brakes and allowing our own Customers – mostly when undertaking modernization and improvement projects, on existing vehicles – to reach out to several professional top suppliers, in a very efficient way!

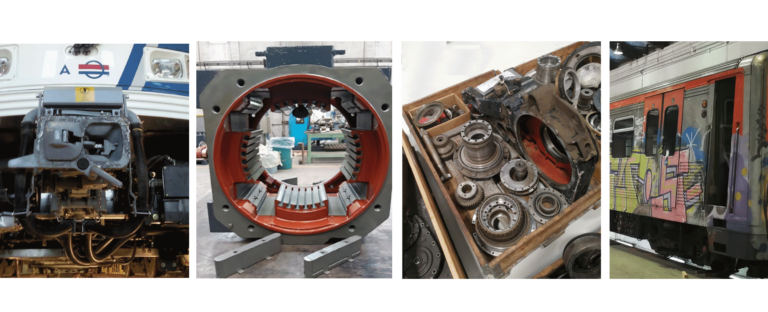

Impressions